Tools

A foam cutter

A foam cutter

![]() There is already plenty of descriptions of

cutting bows (for foam, Depron or other similar materials) especially

on Internet ! However, I will try to put my own modest contribution

to it with a design as simple as possible and a bow which can be

easily adjusted to any size depending on your needs.

There is already plenty of descriptions of

cutting bows (for foam, Depron or other similar materials) especially

on Internet ! However, I will try to put my own modest contribution

to it with a design as simple as possible and a bow which can be

easily adjusted to any size depending on your needs.

List of material:

- A piece of wood (pine) with a 27x27 mm section (length 65 cm),

- A piano wire - diameter 6 mm (2 lengths of 50 cm each),

- 6 junction boxes (section 16 or, even better, 25 mm2),

- A piano wire - diameter 6/10 mm (cutting wire).

Construction:

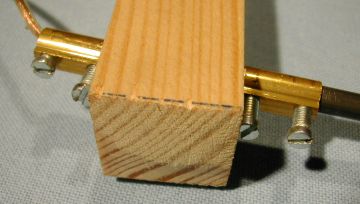

![]() I think the drawing and the pictures below will

give you all the details. The junction boxes are used for fixing and

securing the branches(6 mm music wires) on the back of the bow and

for connection of the power cord as well. The other two junction

boxes used for the attachment of the cutting wire on the branches

have got a groove (machined with a drilling machine or a lathe and a

rat-tailed file) in order to avoid any constraint on the cutting wire

where it is attached. The length of the cutting wire is adjusted to

get the proper tension.

I think the drawing and the pictures below will

give you all the details. The junction boxes are used for fixing and

securing the branches(6 mm music wires) on the back of the bow and

for connection of the power cord as well. The other two junction

boxes used for the attachment of the cutting wire on the branches

have got a groove (machined with a drilling machine or a lathe and a

rat-tailed file) in order to avoid any constraint on the cutting wire

where it is attached. The length of the cutting wire is adjusted to

get the proper tension.

![]() With this design, you can easily change the

diameter of the cutting wire on the same bow. As far as I am

concerned, I use either a 6/10 mm piano wire (feed with about 10 V -

6 A) or a Graupner Ni-Cr 3/10 mm wire, reference 849 (feed with about

12 V - 1,2 A).

With this design, you can easily change the

diameter of the cutting wire on the same bow. As far as I am

concerned, I use either a 6/10 mm piano wire (feed with about 10 V -

6 A) or a Graupner Ni-Cr 3/10 mm wire, reference 849 (feed with about

12 V - 1,2 A).

| |

| |

|

|

|

|

|

|

|

|

|

|

| |

|

| |

Power supply:

![]() It depends on the cutting wire you will use. A

regulated DC power supply adjustable from 0 to 15 V - 10 A (DC) is

suitable for the cutting wires mentioned above. With the dimensions

of the cutter given above and the Graupner wire (ref. 849 -

consumption 12 V - 1,2 A), even a single 12 V battery will do it.

Another idea is to use a battery (12 V for example) associated with

an ESC for electric motor (the one you use in your planes) ; you will

adjust the current using a servo tester (or even your transmitter and

your receiver - throttle channel !).

It depends on the cutting wire you will use. A

regulated DC power supply adjustable from 0 to 15 V - 10 A (DC) is

suitable for the cutting wires mentioned above. With the dimensions

of the cutter given above and the Graupner wire (ref. 849 -

consumption 12 V - 1,2 A), even a single 12 V battery will do it.

Another idea is to use a battery (12 V for example) associated with

an ESC for electric motor (the one you use in your planes) ; you will

adjust the current using a servo tester (or even your transmitter and

your receiver - throttle channel !).

Utilisation:

![]() You will find on the following sites examples and

advice to make use of cutting bows :

You will find on the following sites examples and

advice to make use of cutting bows :

- SeaGull Technologies: The aeromodelling page.

- F5B-UK Web site: Hot wire machine.

- Aeropic: A machine to cut out polystyrene.

![]() On the SeaGull's site, You will also find a

simple foam calculator for cutting trapezoidal wings.

On the SeaGull's site, You will also find a

simple foam calculator for cutting trapezoidal wings.

- For Mac PPC : FoamCalc.PPC

- For PC : FOAMCALC.EXE

Caution !

![]() The fumes emitted while

cutting are extremely toxic. Do not inhale them and work only in a

well ventilated room.

The fumes emitted while

cutting are extremely toxic. Do not inhale them and work only in a

well ventilated room.